- Sonochemistry

The use of sonochemistry has made it possible to carry out numerous organic syntheses, considerably reducing reaction times and improving yields. This technique is based on the phenomenon of acoustic cavitation, by immersing an ultrasonic probe or sonotrode in a reaction medium.

The laboratory’s expertise has been put to good use in the emergence of a new research theme aimed at developing a base of biosourced compounds from flax products for the formulation of new materials.

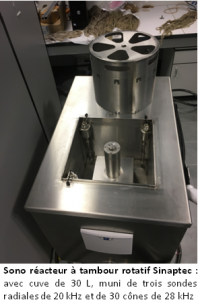

Two different types of ultrasound generator are available: a sonotrode with a frequency of 30 kHz, and a pipe made up of six transducers, each with a frequency of 22 kHz.

At the same time, with a view to possible industrial applications, two semi-pilot sonochemical reactors have been developed for the production of high-quality fibres and the functionalisation of biomass.

Location : IRENE 1st floor, CS team

Contact : François Delattre

- Microwave-assisted synthesis

Microwave-assisted synthesis is an alternative heating technique that generally reduces synthesis times. The laboratory is equipped with two microwaves, enabling the synthesis of a wide range of chemical entities (synthesis of conventional organic products, polymers, inorganic catalysts, solid-phase synthesis).

Location : MREI1 1st étage, CS team

- Isothermal Titration Calorimetry (ITC)

Isothermal Titration Calorimetry, or ITC, is a technique dedicated to the study of molecular interactions in solution. It can be used to determine all the thermodynamic parameters (stoichiometries/number of active sites, affinities, variations in free enthalpy, enthalpy, entropy and heat capacities) associated with any type of molecular organisation or self-organisation.

Our unit has a Microcal ITC200 isothermal titration calorimeter, which is mainly used for the quantitative characterisation of the encapsulation capacities of cyclodextrins (with respect to various volatile organic compounds, bioactive principles, catalysts and catalysis ligands, etc.), the study of the recognition capacities of various proteins (in particular albumin, with respect to bioactive principles), as well as for the study of surface-active properties (critical micellar concentration and enthalpy of micellisation).

Location : MREI1 1st floor, CS team

Contact : David Landy

- Kinematic viscometer

The kinematic viscometer (SVM 3001 Anton Paar) is used in the laboratory to determine the viscosity and density of the deep eutectic solvents developed within the team. Several parameters can be determined, including kinematic viscosity (ASTM D7042, EN 16896, DIN 51659-2), density (EN ISO 12185, ASTM D4052, IP 365), viscosity index (VI) (ASTM D2270), dynamic viscosity (ASTM D7042) and API grades (ISO 91, API 2540, ASTM D1250, IP 200).

Location : MREI1 1st floor, CS team

Contact : Sophie Fourmentin

- The automatic digital polarimeter

By measuring the optical activity or rotatory power of our samples, the polarimeter enables us to carry out quantitative analyses and degradation kinetic studies.

Location : MREI1 ground floor, CS team

Contact : Miriana Kfoury

- Optical tensiometer/drop analyser/ goniometer

The goniometer enables us to measure surface tension and surface tension by contact angle. This is essential for understanding the molecular interaction between liquids and solids, revealing the adhesive properties of a liquid, carrying out wettability studies of materials and surfaces and characterising the surface properties of materials.

Location : MREI1 1st floor, CS team

Contact : Miriana Kfoury

- Total Organic Carbon analyser (TOC-VCSN)

The Shimadzu TOC-VCSN Total Organic Carbon analyser is used to monitor the mineralisation of organic pollutants following degradation reactions (Fenton) or photodegradation (photo-Fenton, photocatalysis). This technique has also been used to study the solubilisation of essential oils by cyclodextrins.

Location : MREI1 1st floor, CS team

Contact : Sophie Fourmentin

- Multirays (Heliosquartz)

The Multirays (Heliosquartz) is a device equipped with 10 interchangeable lamps (UVC, UVB or UVA). It is used to carry out photodegradation reactions of organic pollutants (photolysis, photo-Fenton, photocatalysis) in order to assess the efficiency of different catalysts. It is also used to demonstrate the photoprotective effect of encapsulating bioactive molecules (aromas, essential oils, etc.) in cyclodextrins.

Location : MREI1 1st floor, CS team

Contact : Sophie Fourmentin

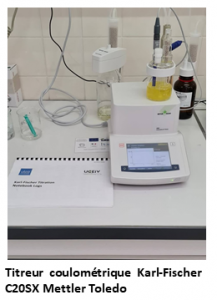

- Karl-Fischer coulometric titrator

The Karl-Fischer coulometric titrator (C20SX Mettler Toledo) is used to measure the water content of various solutions (deep eutectic solvents, cyclodextrin complexes).

Location : MREI1 1st floor, CS team

Contact : Sophie Fourmentin

- Characterisation of materials by gas physisorption (3Flex Micromeritics)

Gas adsorption, generally carried out with nitrogen at a temperature of 77K, is a technique of choice for determining the porous texture, and in particular the specific surface area, of micro-, meso- or macroporous materials. It can also be used to assess the pore volume and pore size distribution of porous materials. Non-destructive, its principle is based on the reversible physisorption of molecules on the surface of a substrate.

Location : MREI1 1st floor, TCEP team

Contact : Renaud Cousin / Lucette Tidahy

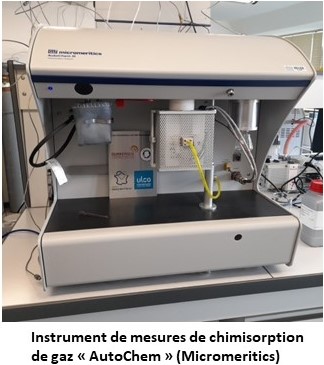

- Characterisation of materials by gas chemisorption (Autochem III Micromeritics)

This device is used to characterise the reactivity of catalytic materials. In particular, it can be used to carry out measurements of :

- reduction at programmed temperature (RTP)

- oxidation at programmed temperature (OTP)

- programmed temperature desorption (DTP)

- and pulsed chemisorption

Location : MREI1 1st floor, TCEP team

Contact : Renaud Cousin / Lucette Tidahy

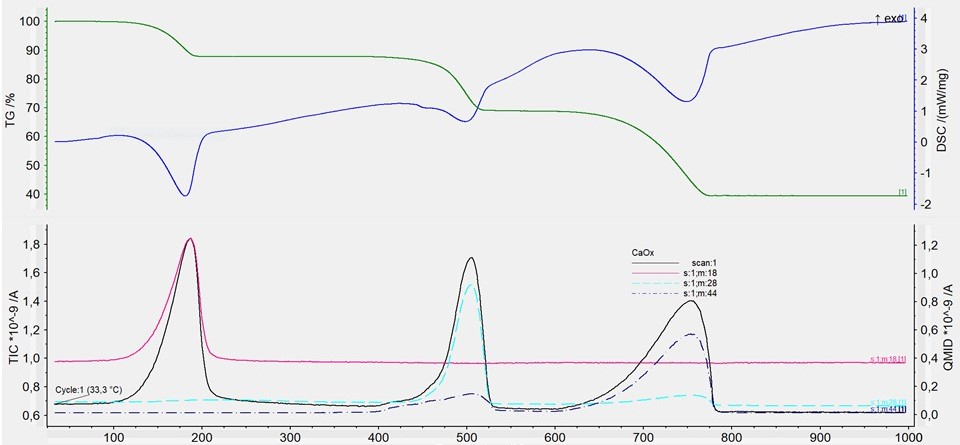

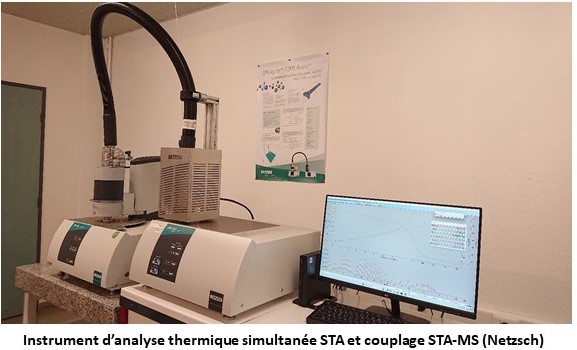

- Characterisation of materials by simultaneous thermal analysis

Thermal analysis makes it possible to study, as a function of time or temperature, the thermal behaviour of any material, mineral or organic, undergoing changes in composition and/or structure, when subjected to a temperature regime in a controlled atmosphere.

The two Netzsch STA 449 F5 Jupiter and Netzsch STA 409 instruments enable the differential thermal analysis (DTA) or differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA) of a sample to be carried out simultaneously. The analyses can be carried out in an oxidising or inert atmosphere from 30 to 1400°C with a heating rate of between 0.001 and 50°C/min.

Differential thermal analysis (DTA) consists of characterising the thermal nature of the physico-chemical transformations of the sample, by measuring the temperature difference between the sample and the thermally inert reference, and provides information on the energetic transformation of the material.

Thermogravimetric analysis (TGA) or thermogravimetry (TG) involves measuring the variation in mass of a sample subjected to a temperature regime, and provides information on the transfer of matter between the sample and its environment.

STA-MS COUPLING

A quadrupole mass spectrometer, QMS Aeolos Quadro, is coupled to the STA 449 F5 Jupiter simultaneous thermal analyser. It is used to analyse the vapours released during chemical transformations of the sample, determining the abundance and nature of the ions formed and separated by a quadrupole filter as a function of their mass/charge ratio, and providing information on the identification of the products formed. The heated transfer system operates at temperatures up to 350°C. Mass range: 1 to 300uma. Detection limit: 100 ppb at a scan speed of 100 u/s. The system’s analysis software enables substances to be identified against a library of materials.

EQUIPMENT

- Netzsch STA 449 F5 Jupiter

- Netzsch STA 409

- QMS Aeolos Quadro

Location : MREI 1, ground floor, TCEP team

Contact : Cédric Gennequin / Lucette Tidahy

- Catalytic test benches

Catalytic installations (2 reactor benches that can operate either in parallel or in series) are used in the following areas :

- for CO2 recovery

- for biogas recovery

The reactors for CO2 recovery consist of two catalytic reactors that can be pressurised, coupled with an analyser equipped with 4 detectors (2 TCD, 1 FID and 1 mass spectrometer). In addition, we have the option of varying the size of the reactors, which will enable us to vary the reaction parameters that may be important for optimising the reaction, or also to move from laboratory scale using powders to semi-pilot scale using shaped materials (extrudates, beads, etc.). Finally, this facility offers the possibility of working from atmospheric pressure up to 80 bar, enabling us to study the methanation reaction right through to the production of alcohols or hydrocarbons. This facility can respond to the major environmental and industrial issues of the moment concerning CO2 recovery.

Location : MREI 1, ground floor hall, TCEP team

Contact : Christophe Poupin / Cédric Gennequin